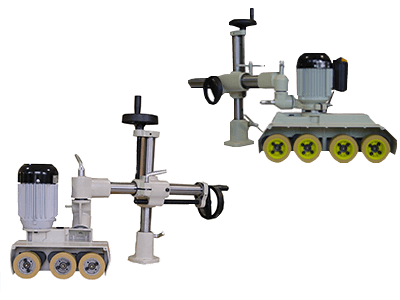

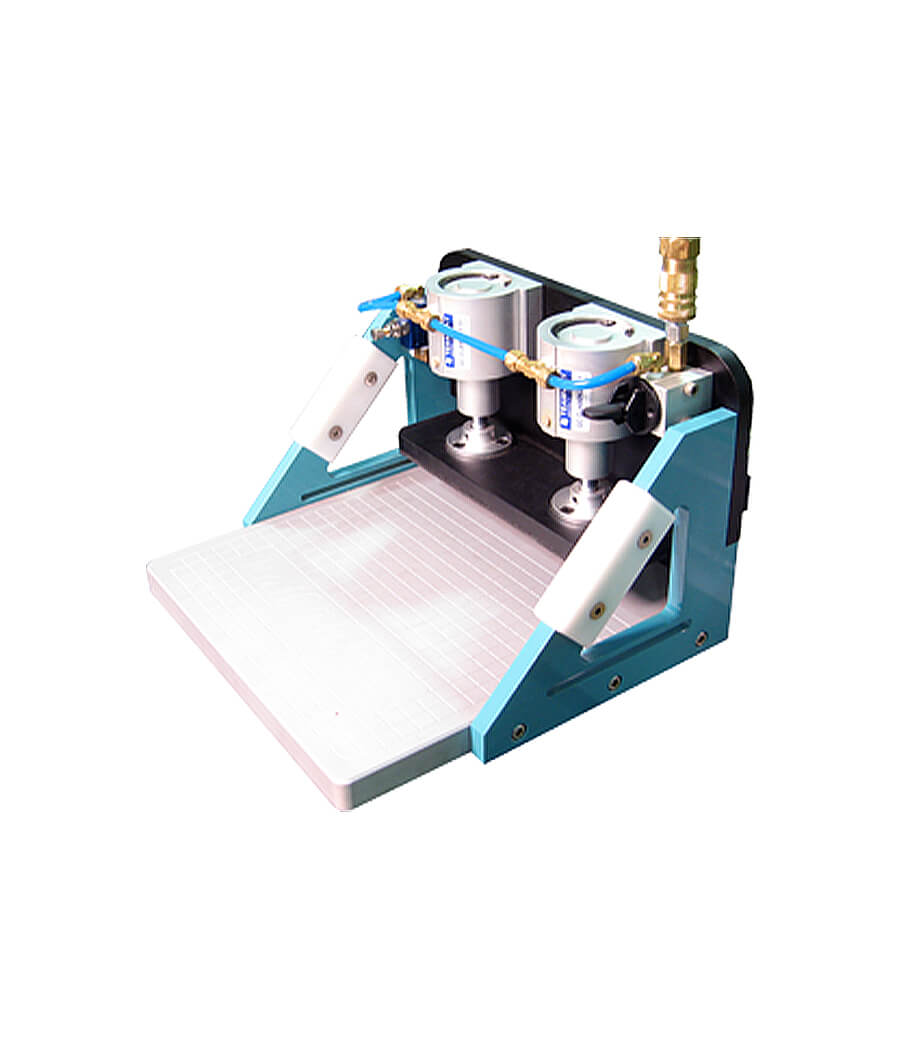

The Rail-Master is the ultimate jig for coping (tenoning) the ends of door rails for 5 piece door system. The Rail-Master firmly clamps the rail down while it floats on a cushion of air using the miter slot for square, consistent and repeatable coping operation.

- Floats on a cushion of air for smooth, easy operation

- Use with material thickness from 3/4″ to 2″ thick

- Proven design for years of trouble free use

- Variable flotation regulation

- Miter bar slides along Miter slot for coping cuts

- Removable miter bar for custom free-floating cuts

- Accepts templates for straight and custom curved and angled cuts

- Slack adjustment feature on miter bar

- Single thumb-lever activation

- Square grid pattern in base to assist in custom cuts

- Constructed of aircraft-grade aluminum, with anodized finish

- Accepts blowout board for splinter-free cuts

- 1 CFM @ 90 PSI

- 800 ft/lbs holding

Thickness Capacity: 3/4″ to 2″

Holding Pressure: 800 ft/lbs

CFM Requirements: 1 CFM @ 90 PSI